Innovate Today

Sustain Tomorrow

Plastic Waste Conversion to Oil / Gas / Carbon Powder

MTD-IDP is an advanced, environmentally friendly solution for waste plastic disposal, transforming plastics into valuable fuels and chemicals. Utilizing cutting-edge depolymerization and pyrolysis technology, it aims to eliminate white pollution, enhance resource recovery, and contribute to a cleaner world through scalable, automated processing lines.

Global Plastic Crisis and Health Risks

The project addresses the urgent global issue of plastic pollution, highlighted by the United Nations Environment Programme’s data showing plastic production exceeding 430 million tons annually. Most plastics are single-use, rapidly becoming waste, with only 9% recycled and the majority landfilled or incinerated. This improper disposal leads to harmful microplastics entering the environment and human bodies, increasing health risks like cancer and neurodegenerative diseases. MTD-IDP targets these challenges by offering a sustainable solution that not only reduces landfill and incineration but also mitigates the environmental and health hazards associated with microplastics.

Innovative Processing and Product Excellence

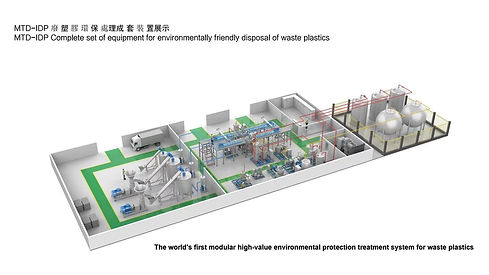

MTD-IDP features a modular, continuous pyrolysis system capable of processing 10–25 tons of mixed waste plastics daily. Its innovative process includes multi-stage crushing, magnetic and optical separation, deep dehalogenation, and thin-film electromagnetic heating reactors. This ensures efficient removal of impurities and precise reaction control. The system produces high-quality products such as light and heavy naphtha, clean diesel, carbon black, and combustible gas, with minimal hazardous emissions. Energy integration and automated management further reduce operational costs and environmental impact, setting new industry standards for safety, efficiency, and product quality.

Strategic Deployment and Future Opportunities

MTD-IDP is being introduced in international markets, including Hong Kong, Macau, and mainland China, with partnerships involving government agencies and logistics authorities. The phased construction plan aims for demonstration lines by 2026, scaling up to multiple processing lines per location. Chemical recycling with MTD-IDP can significantly reduce plastic waste, carbon emissions, and petroleum resource consumption, generating substantial economic value. The technology’s core advantage is its ability to convert waste plastics into high-value chemicals, positioning it as a disruptive force in urban resource recovery and circular economy development, with limitless possibilities for future expansion.